FDC 600

2022-07-29T11:16:41+00:00

THE MOST VERSATILE SINGLE-PASS CARTON PRESS YOU'VE EVER SEEN.

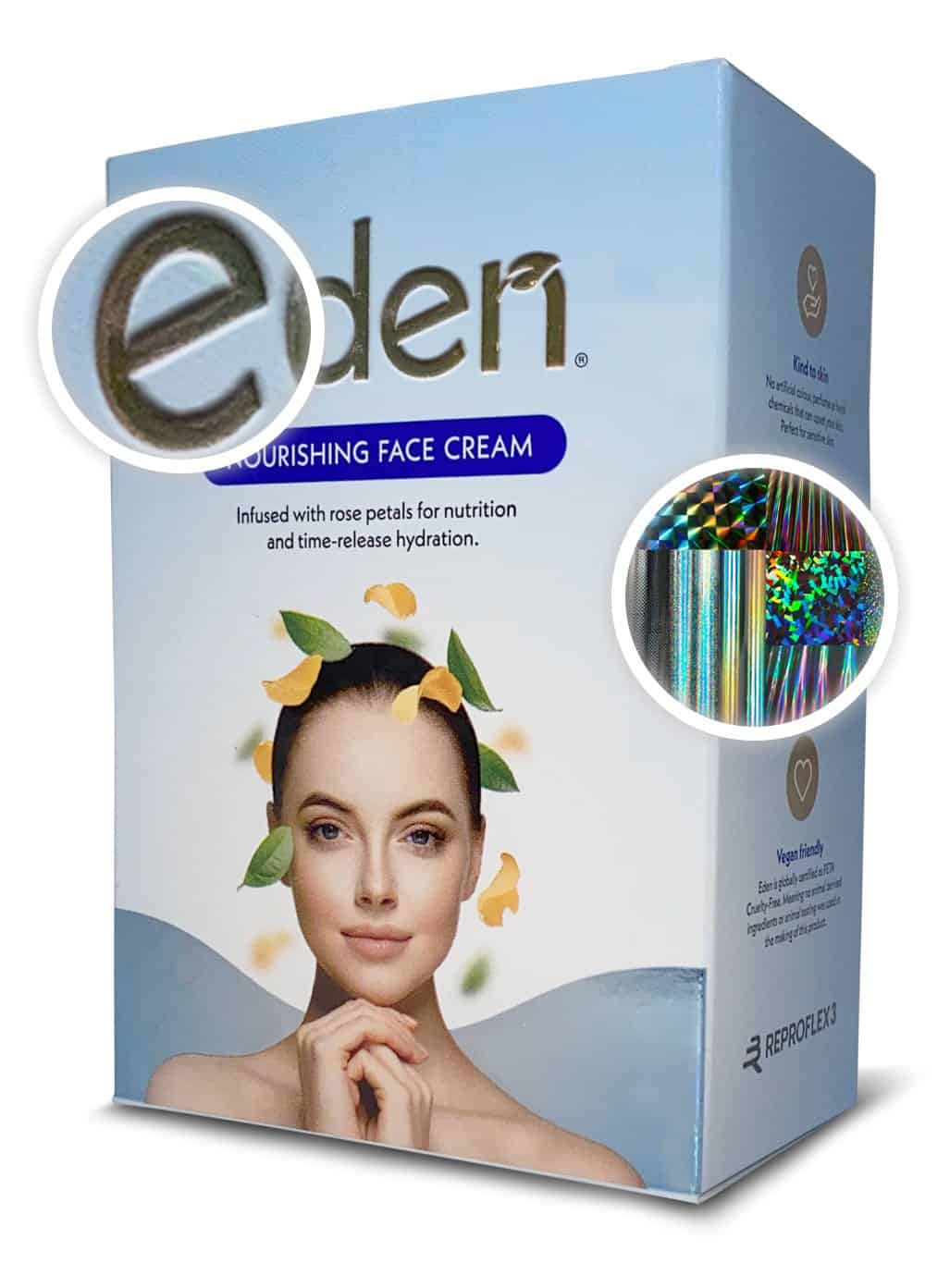

This carton has been produced in a single pass using the Edale FL5, 510mm with inline (FDC) Flatbed Die Cutter.

COLD FOIL

has been laminated on the FL5 Prime full width to give the effect of more costly Met PET cartons.

EMBOSSING

is added inline on the FDC to give a 3D tactile effect.

UNIQUE UNIPRINT

Colours are printed using Edales unique Uniprint print head to ensure the best possible quality.

AIIR SYSTEM

(Autonomous Inking Impression and Registration) on the FL5 gives unparalleled automation and repeatability of quality and print accuracy.

CAST & CURE

has been added to give a finish that adds brand protection and allows the carton to really stand out from other production methods.

CUT, CREASED & STRIPPED

The carton was finally cut, creased and stripped before being discharged onto a conveyor by the FDC 600.

From raw material to finished carton in 1 minute!

ALL IN A SINGLE PASS

THE FDC-600 GIVES YOU ALL THE EFFICIENCY OF A REEL FED SYSTEM AND THE BENEFITS OF FLATBED DIE TECHNOLOGY & VERSATILITY.

Do you want to eliminate your work in progress, reduce the number of operators, waste and power, and give an unrivalled delivery time to potential customers?

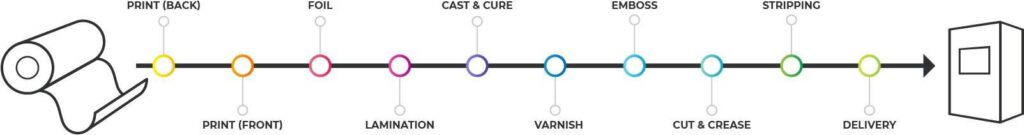

The Edale FDC-600 flatbed die-cutting machine combines the best of sheetfed flatbed die-cutting technology with a cutting-edge servo-driven constant tension web transport system. Specifically designed for fast job change and setup when run in-line with flexo systems or digital lines, the FDC-600 creates a highly efficient web-fed, single-pass folding carton production line.

With a maximum speed of 13,000 impressions per hour, the ability to nest products up to four, pre-registration and the benefit of being able to reconfigure the machine for a wide range of carton sizes and forms without specialist tooling ensures that downtime and substrate wastage is kept to a minimum.

The FDC-600 flatbed die-cutting machine can be retrofitted to an existing Edale, or other manufacturers press or to a roll stand for off-line conversion of analogue or digitally pre-printed webs.

The machine will perform well with a wide range of carton board thicknesses up to 700 microns.

Products can include cutting, creasing, embossing and brail, with delivery being done with a de-nesting system that will ensure easy collection.

A range of other delivery solutions such as a stand-alone Jumbo Unwind and side unloading conveyors and batch stackers are also available.