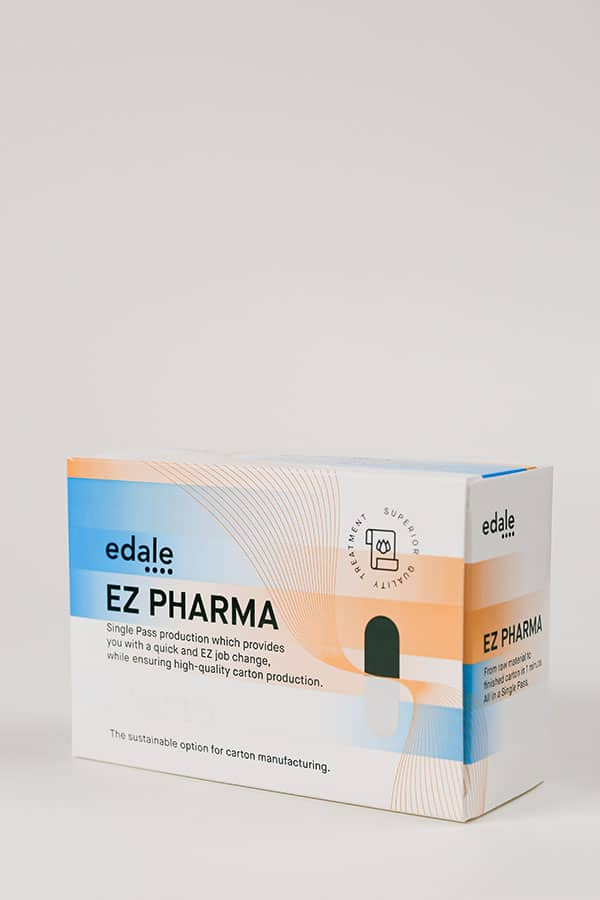

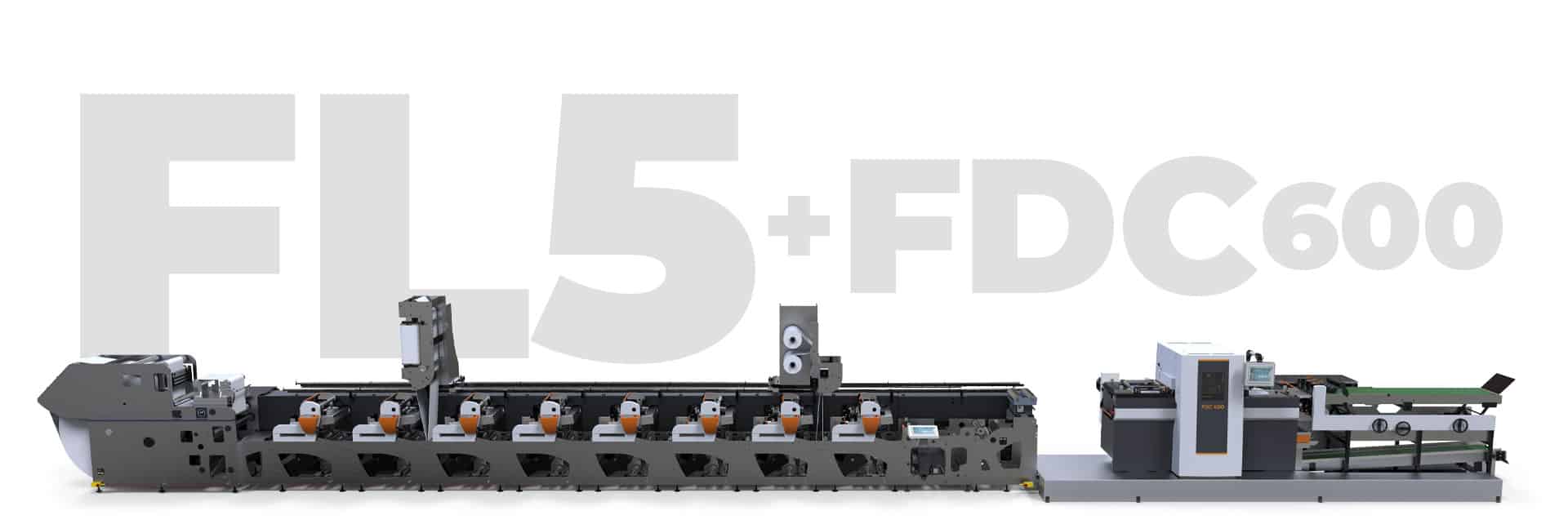

FL5 + FDC 600

2022-06-24T07:28:15+00:00

FL5 CARTON PRODUCTION LINE

CARTON PRODUCTION SIMPLIFIED

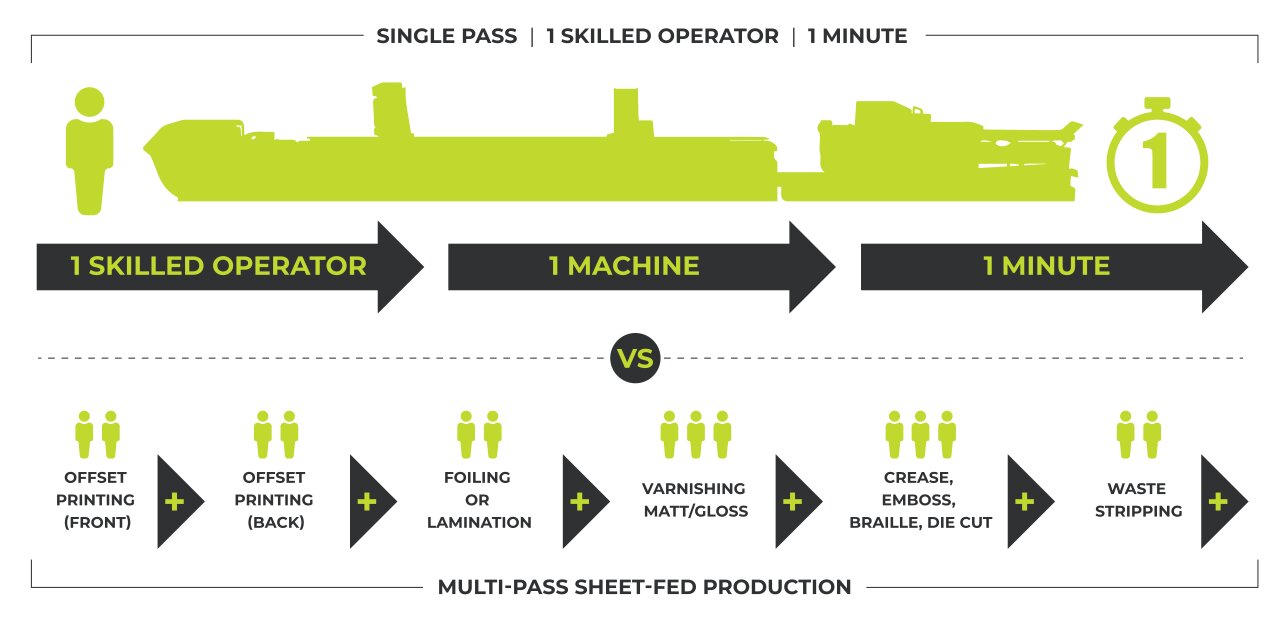

A SINGLE PASS PRODUCTION SOLUTION FOR SUSTAINABLE PAPER BASED CARTONS.

The ground breaking fully automated single-pass carton production line enables you to produce a highly embellished carton in just one step.

You can print, reverse print, foil either hot or cold, laminate, add holographic effects, cast and cure and coat. The FDC-600 can run in line with the FL5, combining low tooling costs with cut, crease, emboss, braille, waste stripping and diverging delivery, all in a single pass.

The FL5 carton production line is ideal for short-run work from 1,000 – 100,000 units and reconfigurable for a wide range of sizes and forms.

Advanced tension control, robust construction and technologies dedicated to handling paper board means that the FL5 can handle substrates up to 700 microns (24pt) thick and 600mm | 23.6” wide.

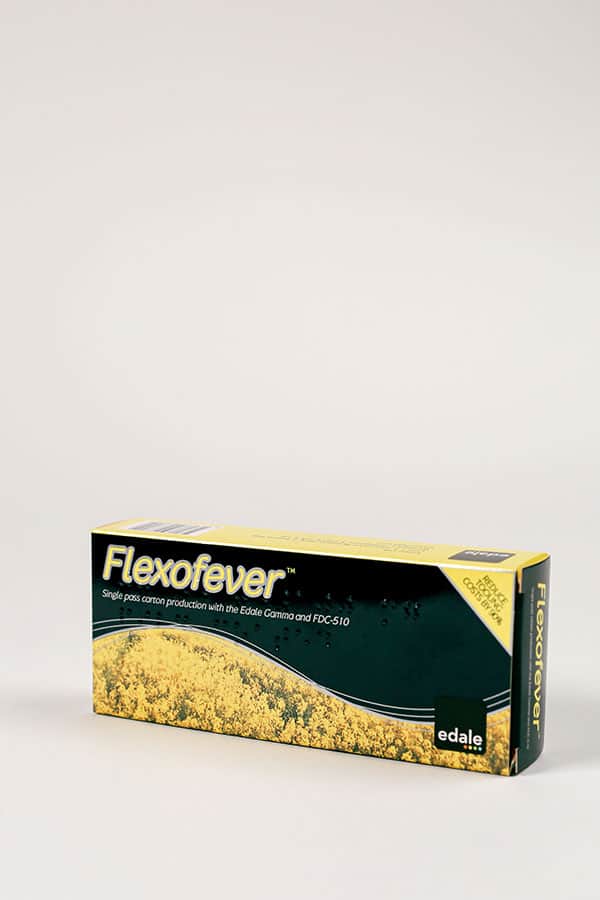

The FL5 carton production line running in line with the Edale FDC-600, web-fed flatbed die cutter, make a highly efficient solution specifically designed for short-run folding carton production.

Book a demonstration and see how the future of embellished cartons can be produced quickly and efficiently on Edale’s unique single pass carton production line.

- Reduced set up and running waste

- Just one operator needed

- Short runs and multiple variations with ease

FROM RAW MATERIAL TO FINISHED CARTON IN 1 MINUTE!

CHALLENGE THE TRADITION

THE ULTIMATE SINGLE-PASS CARTON PRODUCTION LINE

FOR PRINTED, EMBELLISHED, SUSTAINABLE, PAPER BASED DIE CUT CARTONS.

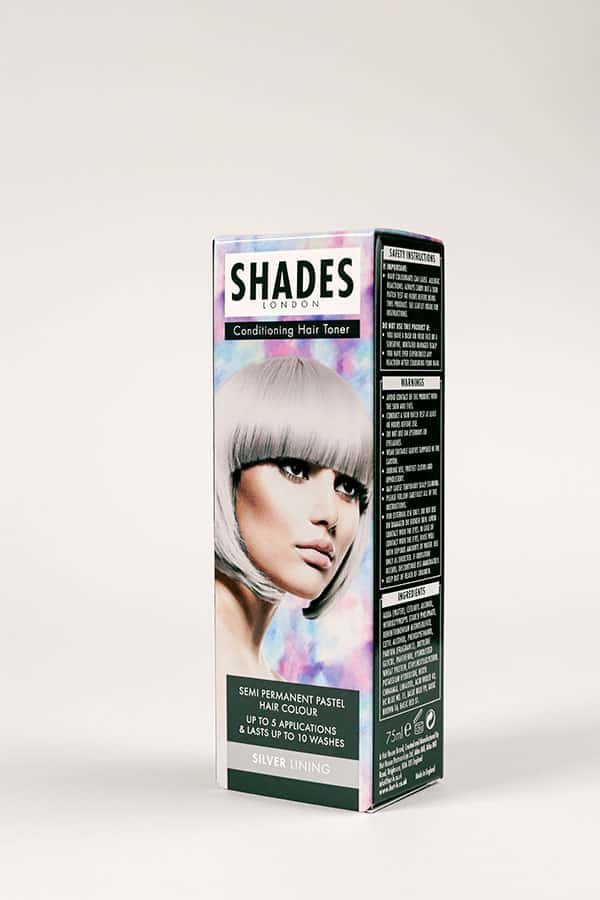

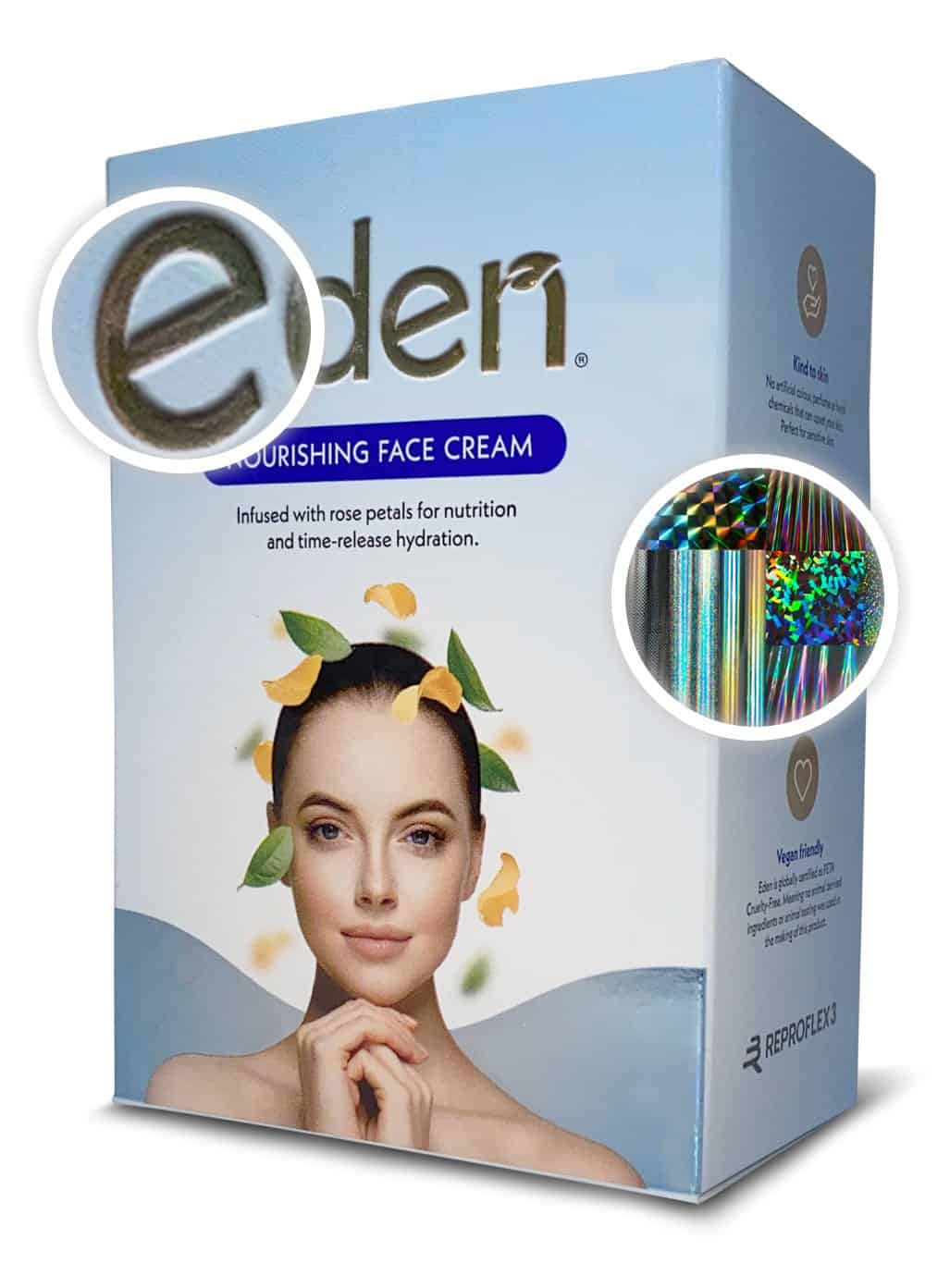

SILVER FOIL

has been laminated on the FL5 Prime full width to give the effect of more costly Met PET cartons.

EMBOSSING

is added inline on the FDC to give a 3D tactile effect.

UNIQUE UNIPRINT

Colours are printed using Edales unique Uniprint print head to ensure the best possible quality.

AIIR SYSTEM

(Autonomous Inking Impression and Registration) on the FL5 gives unparalleled automation and repeatability of quality and print accuracy.

CAST & CURE

has been added to give a finish that adds brand protection and allows the carton to really stand out from other production methods.

CUT, CREASED & STRIPPED

The carton was finally cut, creased and stripped before being discharged onto a conveyor by the FDC 600.

COMBINE, PRINT, CUT, CREASE, BRAIL EMBOSSING AND WASTE REMOVAL IN A SINGLE MACHINE WITH THE FL5 CARTON LINE, IDEAL FOR EMBELLISHED SUSTAINABLE, PAPER BASED DIE CUT CARTONS.

DOWNLOAD BROCHURE

VIEW FL5 IN ACTION

REQUEST A CALL BACK/BOOK A DEMO

VIEW CASE STUDIES

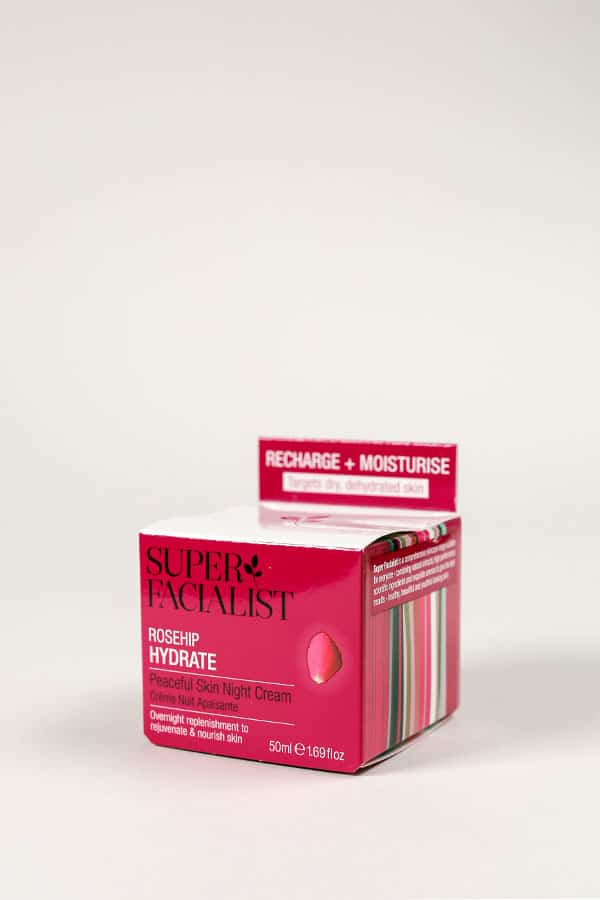

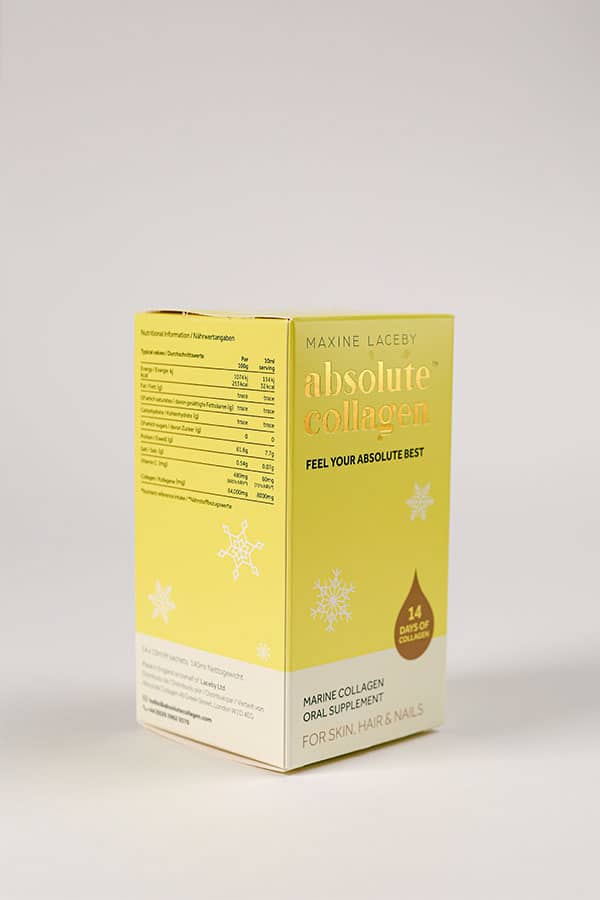

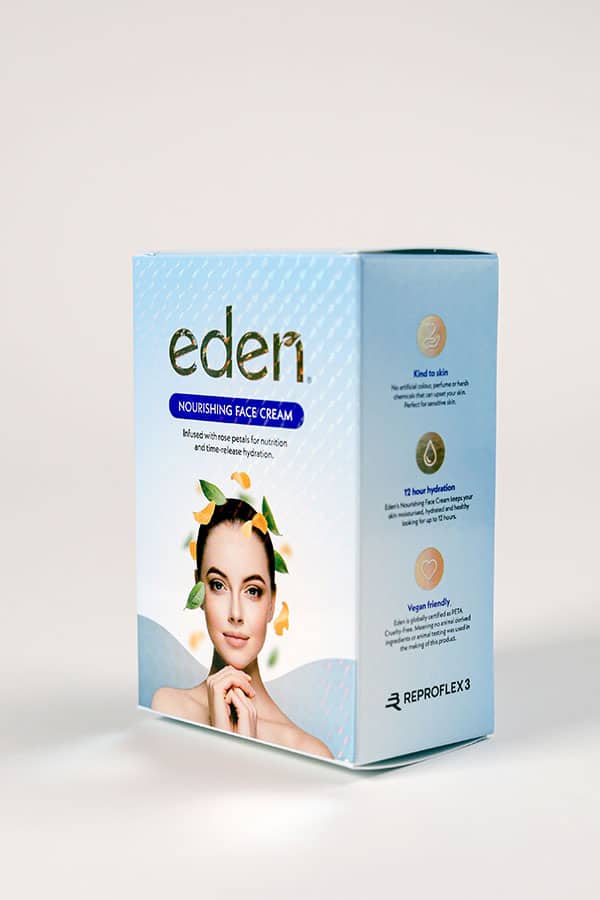

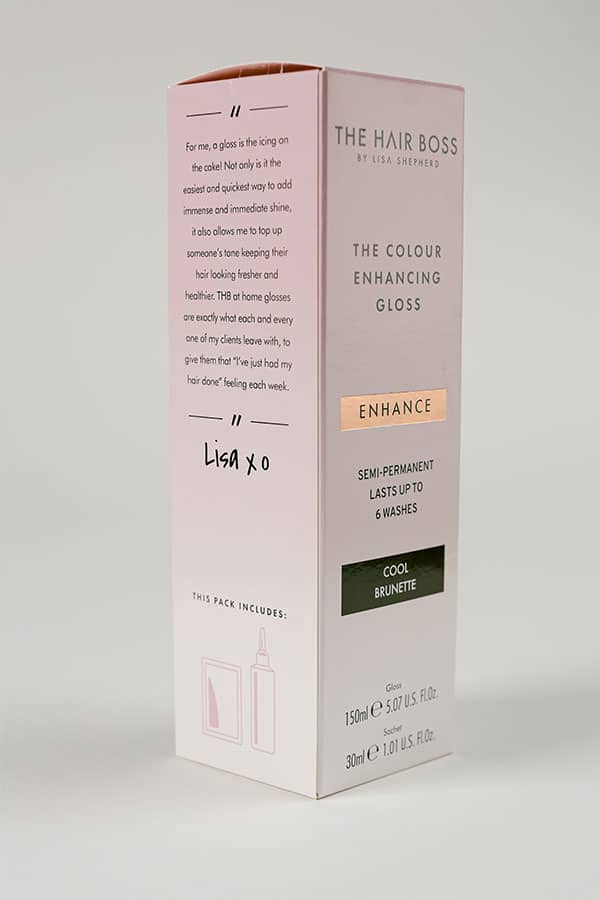

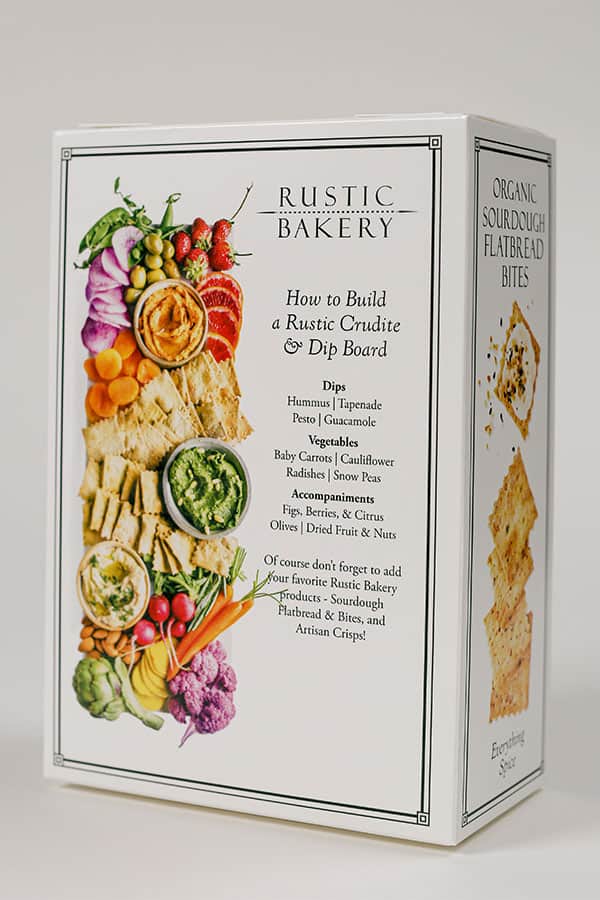

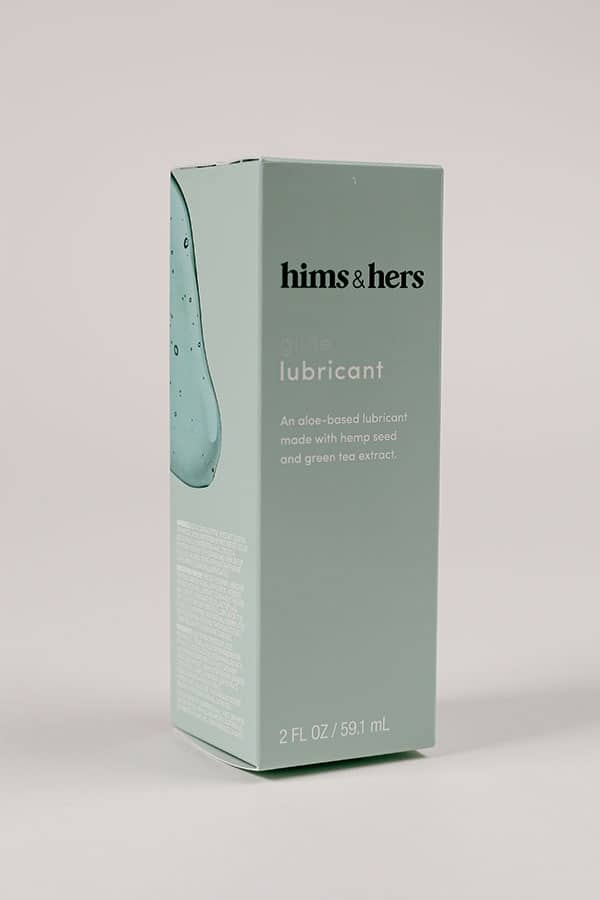

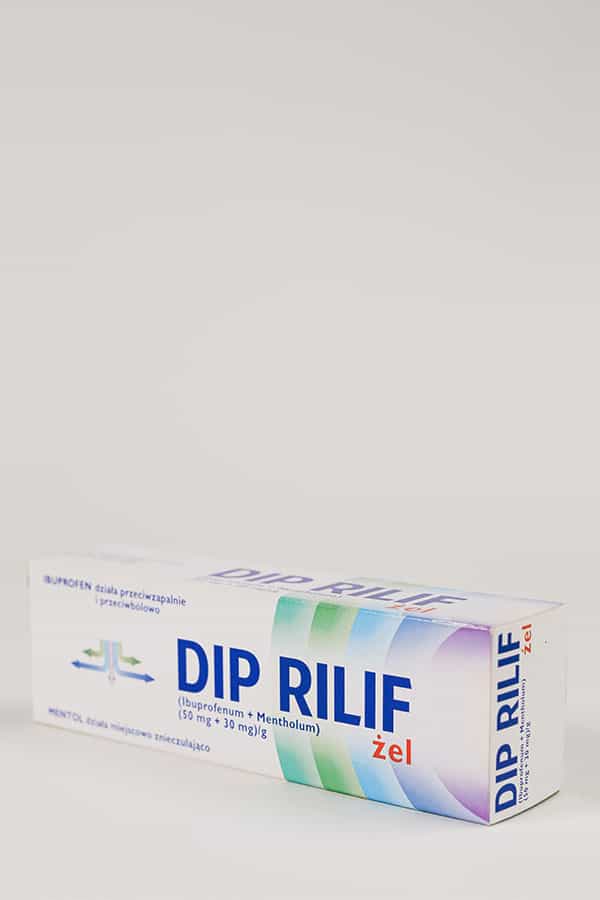

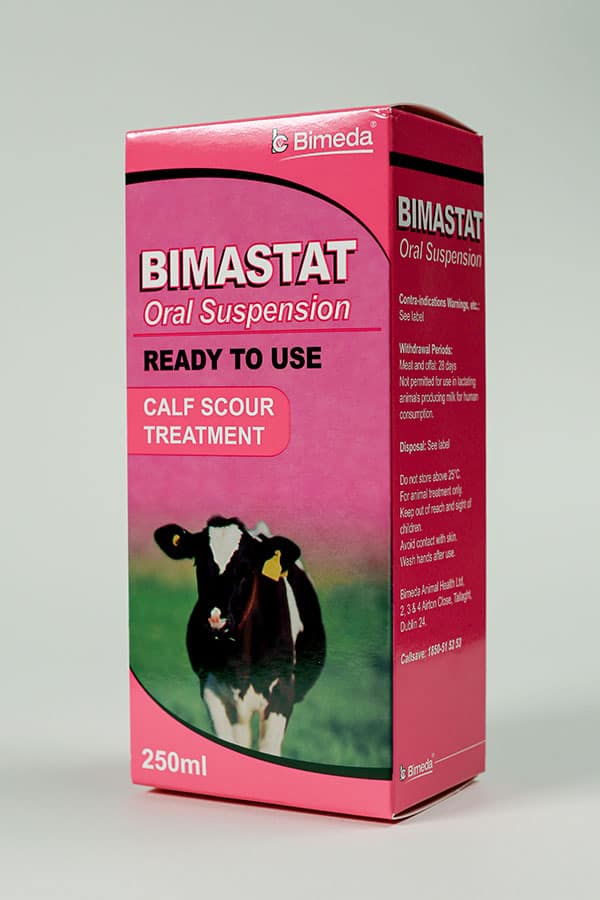

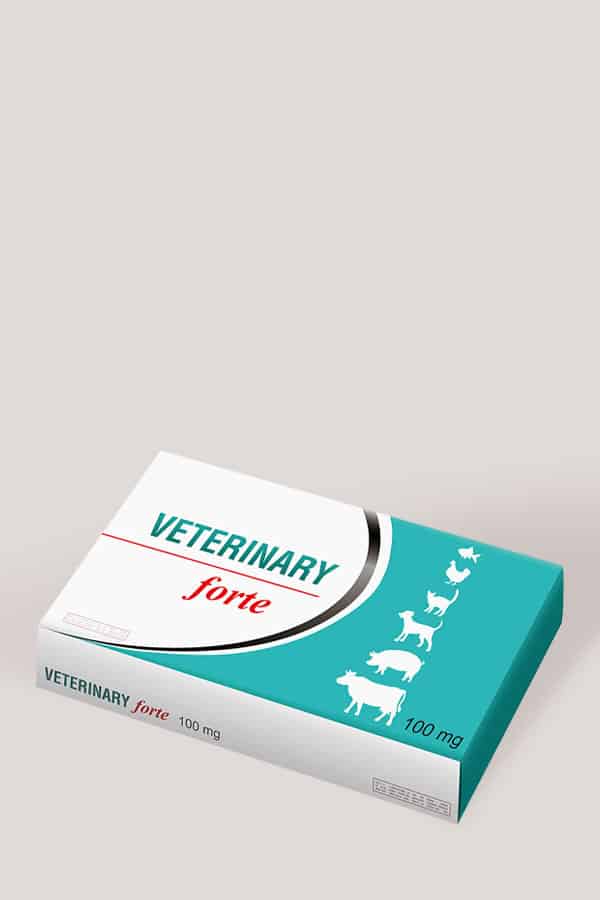

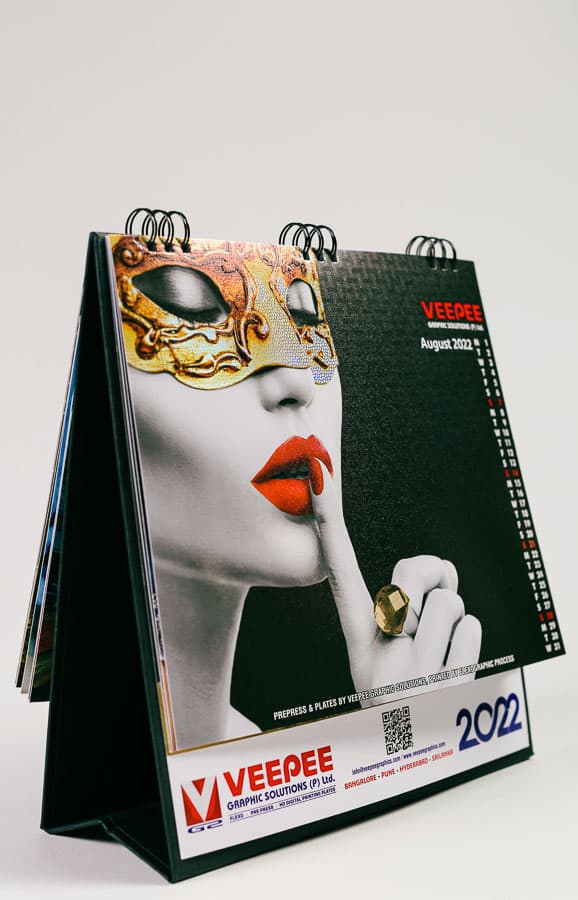

CARTONS PRODUCTION EXAMPLES

Product Technical Specifications

| Product | FL5 | FL7 |

|---|---|---|

| Web widths (inch) (mm) | 510mm | 20” 570mm | 22.4” 650mm | 25.5” | 650mm | 25.5” 760mm | 29.9” 850mm | 33.4” |

| Repeat range (inch) | 8 – 24” 203.2 – 609.6mm | 14 – 36” 355 – 914mm |

| Material range (micron) | 12 – 700 microns 0.5 – 27pt | <700 microns <27pt |

| Mechanical speed (m/min) | 200 m/min | 660 ft/min | 300 m/min | 990 ft/min |